Machine Setup AXIS Parameters

| Axis Address Label Z 90 X 88 |

ASCII code for axis assignments |

| Pulses Per Unit Z 25400.0 X 25400.0 |

The number of encoder pulses (actual or simulated) per unit of travel; generally depends on drive type and drive setup. |

| Encoder Multiplier Z 1 X 1 |

When multiplier is 0, pulses after quadrature are divided by 4; When multiplier is 1, divided by 2; when multiplier is 2, divided by 4. It works backwards Higher multiplier means fewer encoder pulses. |

| Home Position X -13.9800 Z -21.0000 |

The dimension assigned to the machine zero or home position. Sometimes used in rotary axis that do not home at zero. X set so drills do not need A X Tool Length to drill on the spindle center line. |

| Home Direction Z 0 X 0 |

Defines the direction an axis moves when a home is commanded. CW = 0 CCW = 1 |

| Velocity Toward Home Z 100.0000 X 200.0000 |

Sets the velocity at which an axis seeks the home limit switch. |

| Velocity Away From Home Z 10.0000 X 20.0000 |

Sets the velocity at which an axis moves off the home switch |

| Velocity Toward Marker Z 01.0000 X 02.0000 |

Sets the velocity at which an axis searches for the encoder marker pulse |

| Home Sequence Z 2 X 1 |

These numbers determine the order in which the axes seek home: #1 first, #2 next, etc. Axes with the same number home together. 0 will cause that axis not to seek home. |

| Home Switch=0 Marker=1 Z 0 X 0 |

A zero setting commands the normal homing algorithm where the axis finds the switch before finding the marker; with a 1 setting, the axis simply finds the nearest marker. |

| Positive Limit Z 22.0000 X 00.1000 |

Dimension from machine zero where the positive software limit occurs. |

| Negative Limit Z -19.000 X -15.000 |

Dimension from machine zero where the negative software limit occurs. |

| Maximum Feed Z 200.000 . X 400.000 |

Sets the maximum G01, G02, G03 feedrate in inches per minute or mm per minute. High limit is the value for rapid velocity |

| Dry Run Feed Z 75.0000 X 150.0000 |

Sets the dry run feedrate in inches per minute or mm per minute |

| Rapid Velocity Z 0500.000 X 1000.000 |

Set the maximum G00 feedrate in inches per minute or mm per minute |

| Max Acceleration Z 070.000 X 140.000 |

The rate velocity increases or decreases in in⁄sec^2; depends on servo drive⁄motor sizing relative to the axis load being driven. CNC 9000 motion control algorithm manages acceleration to prevent harsh forces. |

| Jerk Limit Z 2000.00 X 4000.00 |

The rate acceleration increases or decreases in in⁄sec^3; a good all purpose value is 2000. High jerk values reduce cycle time; machine motion is more violent. Lower values extend cycle time, machine motion is smoother. These default values are used in the absence of G187, G188, G189 calls. |

| Jog Velocity Z 200.0000 X 400.0000 |

Velocity in IPM or MMPM |

| Jog Key Direction Z 0 X 0 |

Sets whether the Jog is related to moving the Spindle or moving tool. the A “1” reverses direction. |

| Jog Diagonal Distance |

When “checked” JOG distance moved is along diagonal. When “unchecked”, both X and Z move the specified JOG distance. |

| In Position Z 00.0050 X 00.0100 |

After any rapid move, the machine will wait until the axis is within this distance from the target destination before starting the next block. |

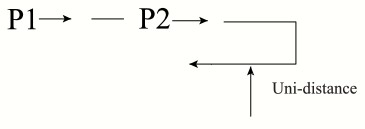

| G00 Unidirectional Z 00.0000 X 00.0000 |

Sets the distance in inches or mm which an axis will go past the destination point in one direction before reversing direction so that the machine will always position from the same direction. Active only in G00 mode  |

| G60 Unidirectional Z 00.0000 X 00.0000 |

Same as G00 unidirectional except only active in a G60 block |

| Backlash Z 00.0002 X 00.0002 |

Backlash compensation in inches or mm. The control compensates for lost motion whenever an axis reversal takes place. Active in all modes. Set when the machine is calibrated |

| Excess Error Z 00.5000 X 01.0000 |

Sets the max distance in inches or mm the machine lags desired position. The CNC e-stops the system if excess error is exceeded. An important safety parameter. A zero value turns off excess error checking. |

| Rotary=0 Linear=1 Z 1 X 1 |

Sets whether the cnc treats an axis as rotary or linear. In rotary, feedrate is interpreted as degrees per minute rather than distance per minute. There is no conversion between inch and metric for a rotary axis. |

| Rotary Rollover Off = 0 On = 1 |

If Rotary Rollover = 1, then all rotary axis positions are modulus 360, i.e., between 0 and 360. An absolute move command goes the shorter way to a target position and hence never goes more than 180 degrees. An incremental move command goes in the direction specified and hence may go more than 180 degrees. If Rotary Rollover = 0, then rotary axis position may range from -1,000,000 degrees to +1,000,000 degrees. Typically set to one for C-Axis |

| Handwheel Normal=0 Invert=1 Z 1 X 0 |

A “1” will reverse the direction of the handwheel. |

| Inch Leading Z 2 X 2 |

Sets the number of characters to the left of the decimal point for the inch system, for the specified axis only |

| Inch Trailing Z 4 X 4 |

Sets the number of characters to the right of the decimal point for the inch system, for the specified axis only |

| Metric Leading Z 4 X 4 |

Same as Inch Leading except for the metric case |

| Metric Trailing Z 3 X 3 |

Same as Inch Trailing except for the metric case |

| Max Handwheel Error Z 00.4000 X 00.8000 |

When handwheeling, if following error reaches this value, pulses from the handwheel are ignored. Error is specified in inches or mm. Prevents excess error e-stop if operator gives a rapid spin to the Handwheel. Max Handwheel Error should be set to Excess Error - .100. |

| Proportional Gain Z 04.0000 X 04.0000 |

Scaling factor between following error and velocity command signal to the drive. Reasonable values are between 2 and 8. |

| Velocity Gain Z 20.0000 X 20.0000 |

Scaling factor between desired velocity and velocity command signal to the drive. Reasonable values are between 10 and 70, these default values used in the absence of G187, G188, or G189. (see below) |

| Handwheel Gain Z 01.0000 X 01.0000 |

Same as proportional gain. Smaller values are used to soften handwheel motion. Reasonable values are between 1 and 4. |