Initial Units are: G20 Inch or G21 Metric to power up in inch or metric

Number of Axes: Can be 1 to 5, normally 2 for lathes

Spindle Axis: Normally set to 1 for Z axis

Primary HDW Encoder: The encoder to use for the primary handwheel.

Normally 3 for 9000 systems

2nd Handwheel Encoder Axis: Used for optional manual panel systems

Remote HDW Encoder: The encoder to use for the remote handwheel, Normally 7.

Remote HDW FOV1 thru FOV4: Sets the feedrate for the four feedrate switch

positions on the remote handwheel

Default Feedrates to: Feed per minute or Feed per rev

Default SpindleSpeeds to: CSS or RPM

Block Skip On: If Yes block skip is on at power up

Optional Stop On: If Yes optional stop is on at power up

Safe Zone On: If Yes safe zone is on at power up.

G22 turns the safe zone off.

G23 turns the safe zone on

UI Style Sheet: Used for alternate UI appearances. Style.dat

Foreign Extension:

Refers to the extension for data files. Current valid extensions are listed below.

NOTE: Shift - F8 will toggle between English and any other language.

CHN CHINESE

ENG ENGLISH

SPN SPANISH

GRM GERMAN

****Tool Table Fields****

The following 10 tool characteristics may be displayed in the tool table.

XLength

Z Length

Radius

X Length Wear

Z Length Wear

Radius Wear

Tool Nose Angle

Tool Mount Angle

Size

Tool Type

X Axis Wear Offset By: Diameter or Radius

****Tool Changer Information****

ATC tool (pocket count): Number of Turret pockets.

Tool Change Macro: Name of the program used for tool change.

Fast Pragati Index: Stop at each turret station or not.

Front Turret: YES for turret on front side.

Clamp on OD: For hydraulic chuck to clamp on OD or ID.

Check Air Pressure: If YES, machine will e-stop if low air is signaled.

Index Turret in HDW: If YES, turret will index in Run-HDW mode.

MCK1 Task File Name: PLC file loaded.

MCK2 Task File Name: PLC file loaded.

MCK3 Task File Name: PLC file loaded.

MCK4 Task File Name: PLC file loaded.

Tool Changer Tag: Used by configurator

Probe Tag: Used by configurator

Coolant Tag: Used by configurator

Spindle Tag: Used by configurator

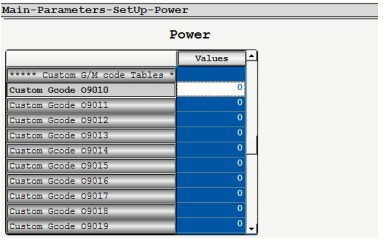

*****Custom G⁄M Code Tables*****

Custom Gcode 09010 Custom Gcode 09011 Custom Gcode 09012 Custom Gcode 09013 Custom Gcode 09014 Custom Gcode 09015 Custom Gcode 09016 Custom Gcode 09017 Custom Gcode 09018 Custom Gcode 09019 Custom Mcode 09020 Custom Mcode 09021 Custom Mcode 09022 Custom Mcode 09023 Custom Mcode 09024 Custom Mcode 09025 Custom Mcode 09026 Custom Mcode 09027 Custom Mcode 09028 Custom Mcode 09029 Custom Mcode 09030 Custom Mcode 09031 Custom Mcode 09032 Custom Mcode 09033 Custom Mcode 09034 Custom Mcode 09035 Custom Mcode 09036 Custom Mcode 09037 Custom Mcode 09038 Custom Mcode 09039 |

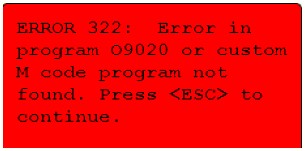

When the G or M code is executed the 090## program (in the ram folder) associated will be called. All custom codes are checked for syntax errors prior to running any program (or MDI command). If an error is found (or the 090## file is not found) a message is shown  ERROR 322: Fehler in Programm O9020 oder Custom M Code Program nicht gefunden. Drücke < ESC > für weiter |